Introduction of successful cases

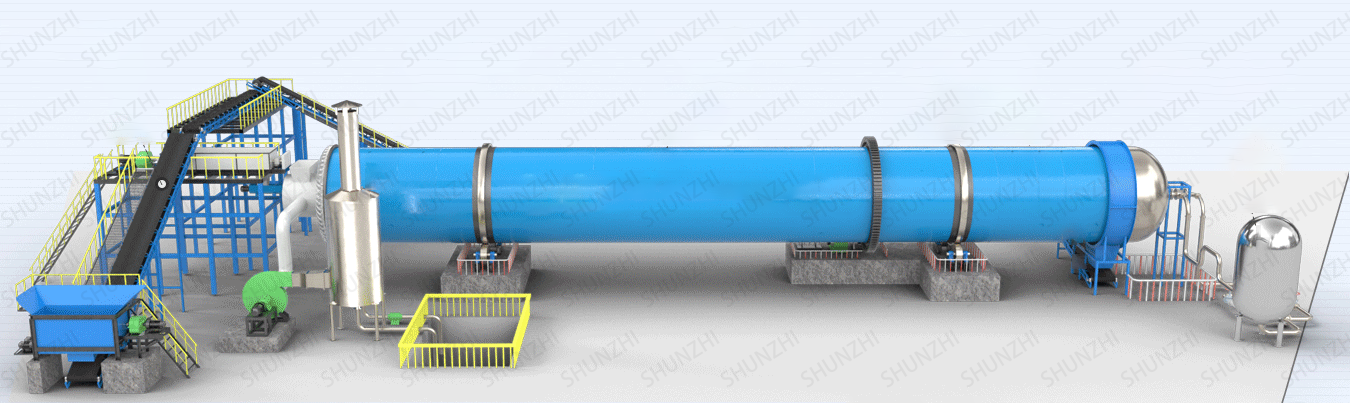

The production line is a sewage sludge drying production line, and the customer requires a production capacity of 150 tons per day. Therefore, our company designed this sludge drying line for customers.

Heat source ①: use natural gas combustion, plus regenerative type to improve the combustion efficiency of natural gas.

Heat source ②: Use biomass pellets, wood chips, branches, straw, coal, etc. as fuel.

Drying equipment: using patented products, dispersing drum dryer. Inside the dryer, there is a high-speed dispersing shaft, which disperses the viscous sludge, solves the problem of the viscosity of the sludge, and also improves the heat exchange efficiency. One, two, three, four, five and six drying process working areas are set up in the dryer. The final moisture content of the material is less than 25%, the entire drying process is completed, and it is discharged from the dryer to enter the next process.

Dust removal and deodorization equipment: The system adopts a four-stage dust removal and deodorization method and a first-stage cyclone dust collector, which can remove dust particles in the exhaust gas. The secondary pickling method is used to remove the odorous gas, the third grade is used to remove the odorous gas, and the fourth grade is used to remove the odorous gas. The final odor gas can be controlled within 2000 dimensionless.

Customer Reviews:

The production line runs very stable. I am very happy to cooperate with Shunzhi Machinery, thank the engineers of Shunzhi Machinery for helping us design this production line, and look forward to working with Shunzhi Machinery again.

TOP

TOP  Email

Email Phone

Phone Online

Online