Product Introduction

Heat source selection:

Steam waste heat heating: equipped with automatic chain exhaust furnace, high and low coal injection furnace, and other coal-fired hot blast stoves, the cost of coal-fired drying is low, but coal-fired pollution is serious. Therefore, in addition to improving the heating efficiency of coal-fired hot blast stoves and tumble drying In addition to the utilization rate of machine heat, the dust removal and purification system is equipped with dry secondary dust removal, dry and wet secondary dust removal, dry and wet multi-stage dust removal and other dust removal equipment, so as to ensure that the coal-fired drying equipment passes the EIA;

Gas and oil heating: mainly use the waste heat of boiler plants, power plants, steam, or heat transfer oil, etc., through the tubular reformer to technically process the steam to meet the drying heat and temperature requirements, and the steam temperature is required to be above 110 degrees You can;

Coal-fired heat supply: natural gas burners, gas generators, fuel-fired engines, etc., build combustion chambers to provide sufficient heat, sufficient combustion, and maximize fuel consumption.

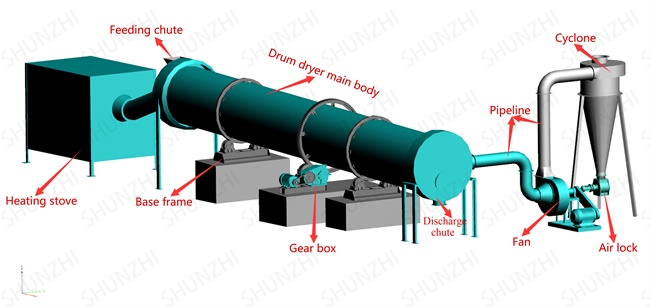

Technical principle and structural composition of brewer's grains dryer:

The brewer's grains dryer production line can quickly make wet brewer's grains with a moisture content of about 85% into high-protein feed materials with a moisture content of about 10% through dehydration, drying, crushing, packaging and other processes. It is composed of dehydration equipment, heat source, feeder, feeder, rotary drum, discharge machine, induced draft fan, unloader and power distribution cabinet, crushing system, packing system and other components; the specific process is as follows. The moisture content is as high as 80% The above wet distiller's grains are squeezed and dehydrated by the dehydration equipment, and then the moisture is reduced to about 65%, and then enters the drying system through the screw feeder. for drying heat and mass transfer. During the drying process, under the action of the inclined copying plate and the heat medium, the brewer's grains are discharged to the star-shaped discharge valve of the brewer's grains dryer to discharge the dried products. The dried brewer's grains processed by this system have good color, fragrant smell and strong animal palatability.

Performance Advantage

1. The drying of brewer's grains has a high degree of mechanization, large production capacity and continuous operation.

2. The brewer's grains dryer has an excellent and simple structure, the material runs smoothly through the resistance of the cylinder, and the operation is convenient.

3. The brewer's grain dryer has less failures, low maintenance costs and low power consumption.

4. The uniformity of product drying is good.

5. The product has no peculiar smell after drying.

Equipment Pictures

Customer Site

Technical Parameter

| Specification(m) | Cylinder volume | Capacity | Installation slope | Max intake air temperature | Main motor | Total weight |

| (Diameter x Length) | (m³) | (t/h) | (%) | (℃) | (kw) | (t) |

| Φ1.2×8.0 | 9 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |

| Indirect heat transfer dryer | ||||||||

| Cylinder diameter × Cylinder length | Inner diameter of outer cylinder (mm) | Inner cylinder inner diameter (mm) | Cylinder length (m) | Cylinder volume (m³) | Cylinder slope | Lifting plate type | Maximum intake air temperature (℃) | Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | lift type | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | lift type | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.1 | 3-5% | lift type | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 | ||||||

TOP

TOP  Email

Email Phone

Phone Online

Online