Product Introduction

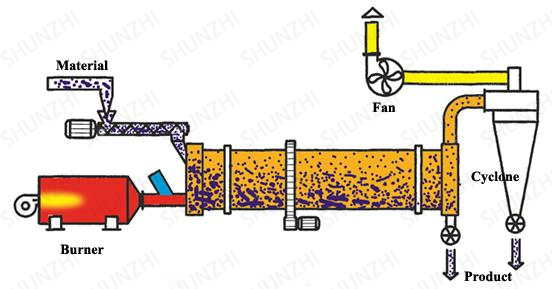

The bituminous coal dryer equipment mainly consists of a heat source device, a feeding device, a drying host, a discharging system, a dust removal system, and a control system. The bituminous coal that needs to be dried is mainly in the discharging area, the inclined lifting plate area, Drying in cleaning area and guide area.

The bituminous coal dryer is a slightly inclined and rotatable cylinder. The wet material enters from the upper part of one end, and the dry material is collected from the lower part of the other end. The hot air enters from the feed end or the discharge end, and is discharged from the upper part of the other end. The drum is equipped with a forward copying board, so that the material is continuously picked up and sprinkled during the rotation of the drum, so that it is fully in contact with the hot air flow, so as to improve the drying efficiency and move the material forward. The heat source of the drying material is generally hot air, high-temperature flue gas, etc. It can be selected according to the nature and quality requirements of the material.

Performance Advantage

1. Combined lifting board

According to the changes in the physical properties of the material during the drying process in the bituminous coal dryer, a combined lifting plate with multiple structures is used to make the material form a uniform material curtain in the cylinder, and conduct sufficient heat and mass transfer with the hot flue gas. For high-humidity viscous materials, there will be a chain-breaking device to prevent clogging, blocking materials and breaking the ball. For materials with particularly good fluidity, spoon-shaped arc plates are used. As a result, the evaporation intensity per unit volume can reach 40~80kg/m3.h, and the evaporation intensity is increased by 50~99% compared with the traditional coke dryer.

2. Self-aligning supporting wheel device

The bituminous coal dryer adopts a different bearing model and structure from the supporting roller of the traditional coke dryer. The supporting roller and the tire belt are self-constrained to maintain line contact, and the friction surface contact is wider and balanced, ensuring the service life of the supporting roller and the tire belt. Enhance the stability of the cylinder operation. And appropriately reduce the angle between the supporting wheels, reduce running resistance, and reduce power consumption.

3. Reasonably adjust the speed

According to the different physical and chemical properties of the drying materials, the drying residence time is different. The design adopts the ideal rotation speed to fully ensure the drying quality. Generally, electromagnetic speed regulation or frequency conversion speed regulation motor is used.

4. Dust collecting tail cover design

According to the requirements of different drying materials, the bituminous coal dryer expands the cavity to design the tail cover and change the tail airflow direction, so that the tail cover can take the primary dust collection function, which greatly reduces the dust collection pressure of the subsequent dust collector.

5. New type of sealing device

The front and rear sealing rings of the bituminous coal dryer draw lessons from the sealing device of the rotary kiln, and are composed of a labyrinth device, which is resistant to temperature and abrasion, has a good sealing effect, a long service life, and is easy to install and maintain.

Equipment Pictures

Customer Site

Technical Parameter

| Specification(m) | Cylinder volume | Capacity | Installation slope | Max intake air temperature | Main motor | Total weight |

| (Diameter x Length) | (m³) | (t/h) | (%) | (℃) | (kw) | (t) |

| Φ1.2×8.0 | 9 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |

| Indirect heat transfer dryer | ||||||||

| Cylinder diameter × Cylinder length | Inner diameter of outer cylinder (mm) | Inner cylinder inner diameter (mm) | Cylinder length (m) | Cylinder volume (m³) | Cylinder slope | Lifting plate type | Maximum intake air temperature (℃) | Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | lift type | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | lift type | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.1 | 3-5% | lift type | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 | ||||||

TOP

TOP  Email

Email Phone

Phone Online

Online