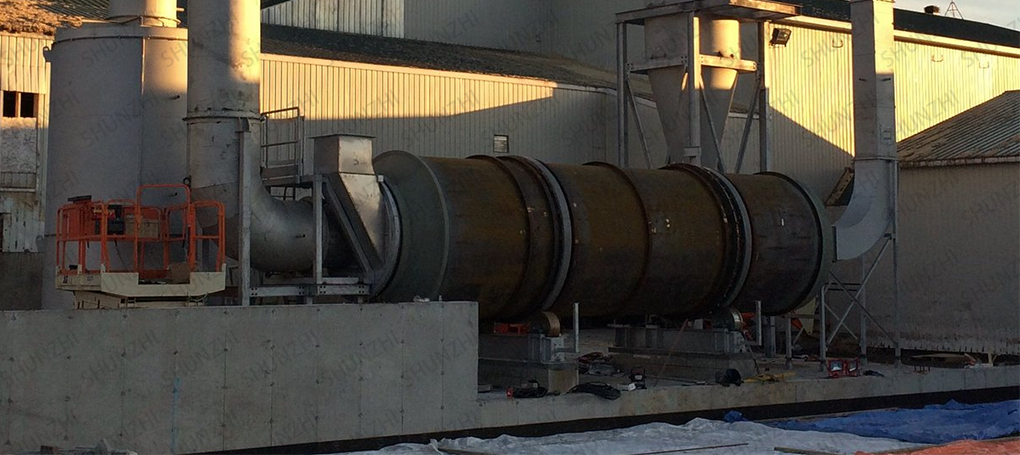

Introduction of successful cases

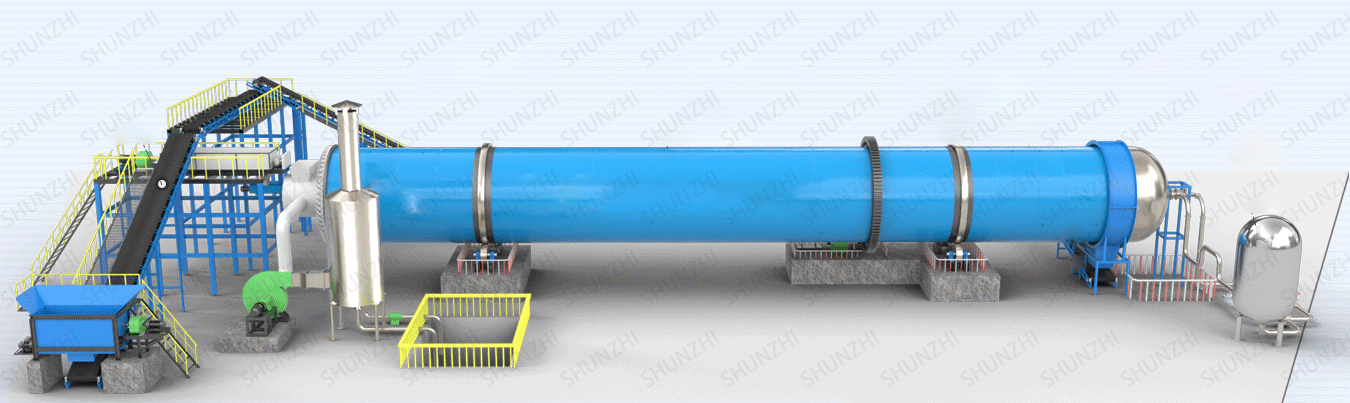

The production line is a bentonite drying production line customized according to customer requirements. The customer requires a production capacity of about 300 tons per hour, so our company has designed such a production line in detail for the customer.

The equipment adopts the downstream drying process, and its working principle is as follows: After the bentonite enters the drying drum, it is divided into the following working areas: First, the material guide area, the bentonite enters this area and contacts with the high temperature hot air to quickly evaporate the water, and the bentonite guides the material in the large lead angle. When the board is moved, it is led into the next working area; the second is the board copying area, where the bentonite is picked up by the copying board to form a material curtain state. At this time, the bentonite is fully contacted with the hot air, and the moisture in the bentonite quickly evaporates and peels off into water vapor. , the water vapor is then drawn away by the induced draft fan, so as to achieve the purpose of drying the bentonite; the bentonite is dried in this area into a loose state with a moisture content of less than 5% (or lower), and the bentonite reaches the required moisture state after heat exchange. Enter the discharge area at the back; the third is the discharge area, where the drum does not have a copy board, and the bentonite rolls and slides to the discharge port in this area to complete the entire drying process.

Customer Reviews:

Shunzhi Machinery designed and customized this production line according to our requirements, which helped us save a lot of costs. I am very grateful to Shunzhi Machinery and look forward to the next cooperation with them.

TOP

TOP  Email

Email Phone

Phone Online

Online