Introduction of successful cases

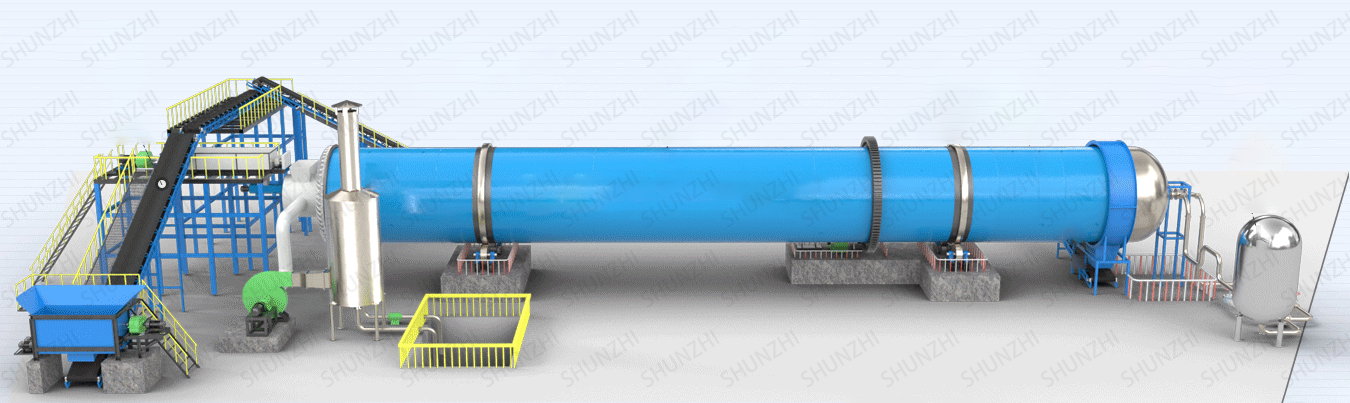

This production line is an ore powder drying production line, and the customer requires a production of 300 tons per day, so our company has designed such a production line in detail for the customer.

The working principle of this set of equipment is as follows: after the wet mineral powder enters the drying drum, it is divided into the following working areas: first, the material guide area, the wet mineral powder enters this area and contacts with high temperature hot air to quickly evaporate the water, and the mineral powder guides the material in the large lead angle. When the plate is moved, if no bond is formed, it will be led to the next working area; the second is to pick up the cleaning area, where the wet material is picked up by the plate to form a material curtain state, and it is easy to form a phenomenon of sticking to the drum wall when the mineral powder falls. , in this area, because the equipment is designed with a cleaning device, the cleaning device can reasonably clean the mineral powder adhered to the inner wall. In this process, the cleaning device also plays a role in breaking the agglomeration of the mineral powder balls, thereby increasing the heat exchange. The third is the inclined lifting plate area, the wet mineral powder has been in a loose state with low moisture in this area, and the mineral powder has no bonding phenomenon in this area. After sufficient heat exchange, the mineral powder meets the requirements. The fourth is the discharge area, the drum does not have a copy plate in this area, and the mineral powder rolls and slides to the discharge port in this area to complete the entire drying process.

Customer Reviews:

The production line designed by Shunzhi Machinery for us is perfect. The output meets our requirements. The labor cost is low and the operation is simple, thank you very much.

TOP

TOP  Email

Email Phone

Phone Online

Online