Introduction of successful cases

The production line is a brewer's grain drying production line, and the customer's request is not high, so we have equipped the customer with a tube bundle dryer, which is not only easy to operate, but also meets the requirements.

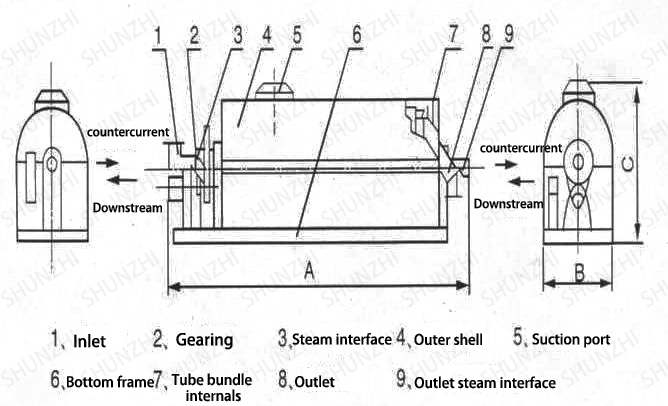

The material enters the inner layer of the rotary drum from the feeding device to realize downstream drying, and the material moves to the other end of the inner layer and enters the middle layer for countercurrent drying. The material travels to the other end of the middle layer and falls into the outer layer, the material travels in a rectangular multi-loop way in the outer drum, and the material that achieves the drying effect travels quickly and discharges the drum under the action of hot air. Due to its own weight, it cannot travel quickly, and the material is fully dried in this rectangular copy board, thereby completing the drying purpose.

Customer Reviews:

We compared many companies, and finally decided to choose Shunzhi Machinery. Shunzhi Company designed and installed this production line for us, and it was perfect in every aspect!

TOP

TOP  Email

Email Phone

Phone Online

Online