Introduction of successful cases

This production line is a ceramsite sand production line. According to the customer's output and other requirements, we have matched a complete production line for the customer, from crushing to grinding and incineration. Perfect realization of customer requirements.

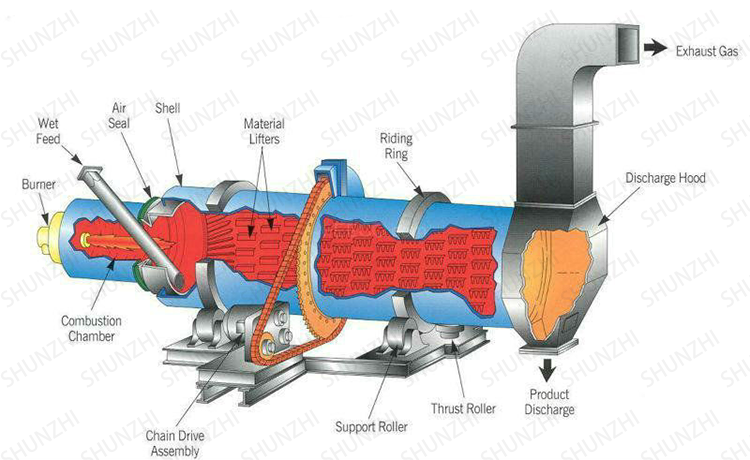

The production line uses jaw crusher to crush bauxite, and then uses a ball mill for drying and grinding, and a high-efficiency powder separator to form a closed-circuit system for material grinding. The raw powder after grinding is sent to the screening device by the belt conveyor, the qualified ones are sent to the rotary kiln, and the oversized ones are returned to the raw material mill. The material is sent to the rotary kiln for calcination into ceramsite sand, which can be directly transported to the multi-stage vibrating screen after the cooling machine, and divided into multiple particle size grades according to the requirements. The production line system has a high degree of automation and a continuous process. When equipped with a bag filter, it can reduce the dust pollution of the production line and purify the working environment of the post. The hot air for drying the material comes from the waste gas of the rotary kiln, so that the waste heat can be utilized, which greatly saves the capital investment.

Customer Reviews:

We discussed with Shunzhi Machinery for a long time, and inspected their factory on the spot, and finally chose Shunzhi Machinery to help us configure this production line, and the result was perfect.

TOP

TOP  Email

Email Phone

Phone Online

Online