Introduction of successful cases

The production line is a new type of cement dry production line. According to the customer's requirements, we designed and installed the entire production line for the customer. The production line adopts new raw material, fuel homogenization and energy-saving grinding technology and equipment. The whole line adopts computer distributed control to realize the automation of the cement production process with high efficiency and low consumption. ,environmental Protection.

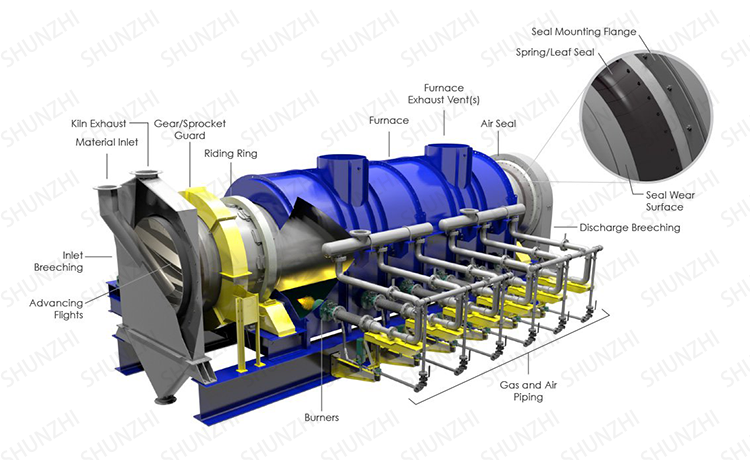

The new dry-process cement production line is mainly composed of processes such as crushing and pre-homogenization, raw meal preparation and homogenization, preheating and decomposition, cement clinker firing, cement grinding and packaging, etc. The raw materials are dried and ground at the same time, or dried first. After drying, it is ground into raw meal powder, and then the raw meal powder is fed into the cement rotary kiln to calcine the clinker, and then the clinker is added with an appropriate amount of gypsum (sometimes mixed with mixed materials or admixtures) and ground with a MBS rod mill. made. The production line can provide users with advanced high-efficiency vertical drum preheaters and five-stage cyclone preheaters, which are stable in operation, solid in structure and high in quality.

Customer Reviews:

It is the first time for us to purchase machines from China. After comparing several rotary kiln products and inspecting many manufacturers, we finally chose to cooperate with Shunzhi Machinery. It is a pleasure to cooperate.

TOP

TOP  Email

Email Phone

Phone Online

Online