Introduction of successful cases

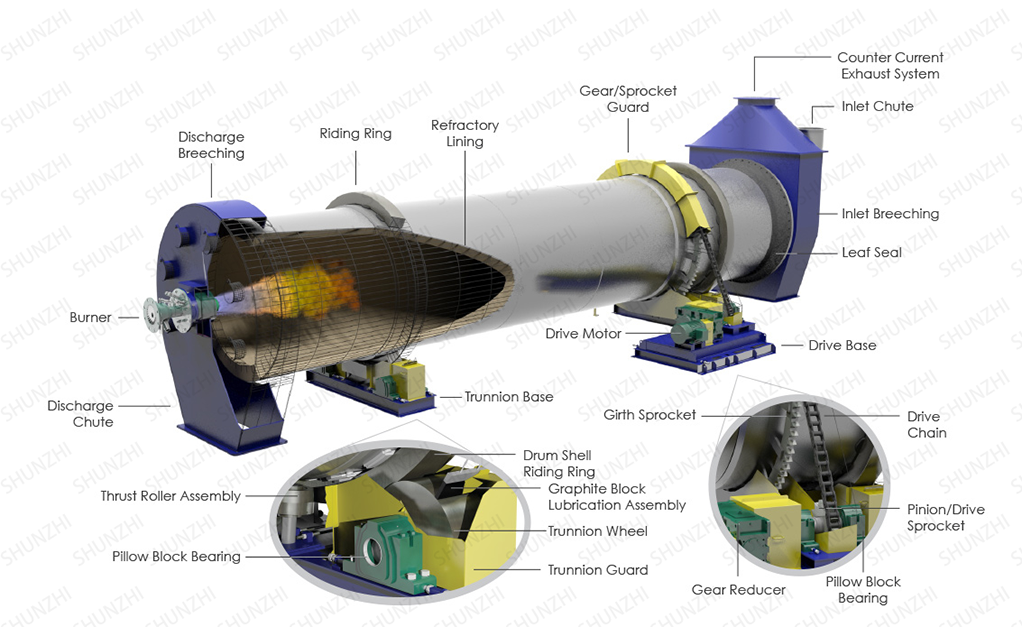

This production line is a lime rotary kiln production line. The company has set up a production line designed according to customer requirements, which can not only burn small-grained limestone, but also heat evenly and have high product activity.

The limestone is sent to the preheater through the elevator for heating, and then sent to the lime rotary kiln to be calcined and decomposed. The limestone generated after decomposition enters the cooler to be cooled, and then sent to the finished product warehouse through the belt conveyor after cooling. The limestone rotary kiln production line configured by our company has advanced technology and simple structure. The preheater can effectively improve the preheating effect. The decomposition rate of preheated limestone into the kiln can reach 20-25%, which effectively improves the output of the rotary kiln. , reducing heat consumption.

Customer Reviews:

We are very satisfied with the cooperation with Shunzhi Machinery this time. The production line they configured has a high output and the lime powder produced has a good particle size. Thanks to Shunzhi Machinery.

TOP

TOP  Email

Email Phone

Phone Online

Online