Product Introduction

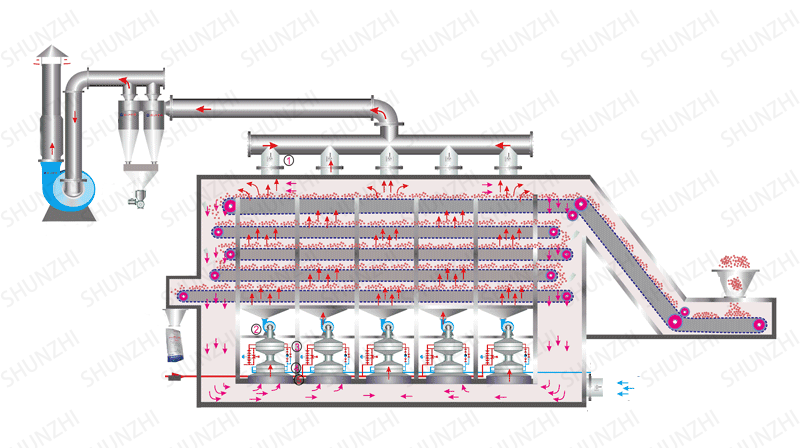

The raw material is evenly fed onto the mesh belt/plate belt by the distributor. The mesh belt/plate belt is pulled and moved in the dryer by the drive unit. The dryer consists of several independent drying sections. Hot air circulates independently in each section. Part of the moist air will be exhausted by the exhaust fan. The hot air penetrates the belt from top to bottom or bottom to top, thus completing the heat and mass transfer process. The belt movement speed is adjustable. The upper and lower circulation units can be freely configured according to customer requirements.

Performance Advantage

1. Different heating and circulation methods are available.

2. The length, width and layers of the belt are designed according to production needs.

3. The pre-dehydration process of the machine can remove a large amount of water on the surface of the leaves, thereby reducing the drying intensity and energy consumption.

4. The special hot air drying system improves the permeability and drying speed of the material.

5. The adjustment of the belt speed and the temperature control of different sections ensure the drying time and the quality and color of the material.

6. A strong magnetic iron removal device can be selected to effectively remove metal impurities.

Equipment Pictures

Customer Site

Technical Parameter

| Model | BX-1.5*6m | BX-2*8m | BX-2*9m | BX-2*10m | BX-2*12m |

| Area of dry(m2) | 36 | 64 | 72 | 80 | 96 |

| Thickness of the material | 50-200mm | ||||

| Operation temperature | 40-120℃ | ||||

| Drying time | 0.5-5 hours | ||||

| Motor power | YCT-1.1kw | YCT-1.5kw | YCT-1.5kw | YCT-2.2kw | YCT-3kw |

| Evaporation capacity | 300-500kg/h | 300-500kg/h | 300-500kg/h | 300-500kg/h | 300-500kg/h |

| The size of input furnace | 3.2*1*2.7 | 3.9*1.26*3 | 3.9*1.26*3 | 4.7*1.5*3 | 4.7*1.5*3 |

| Fan | 11Kw | 15Kw | 15Kw | 22Kw | 30Kw |

| Exhaust fan | 1.5Kw | 3Kw | 3Kw | 3Kw | 4Kw |

| Output conveyor | 0.12Kw | ||||

| Total power | 14.9Kw | 20.7Kw | 24.2Kw | 28.4Kw | 37.2Kw |

TOP

TOP  Email

Email Phone

Phone Online

Online