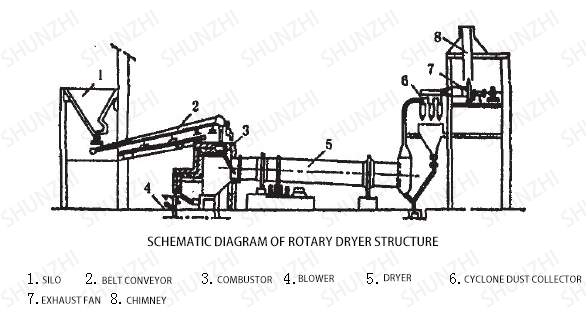

Process Flow Details

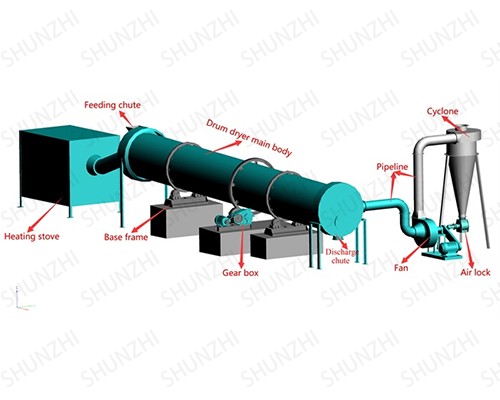

Industrial dryers are also called rotary dryers or tumble dryers, because this type of dryer consists of a cylindrical jacket. The cylinder is placed on the supporting wheel on the ground, and there is a circle of gears on the cylinder wall of the cylinder. The gear is driven by a motor, and the cylinder will rotate during the working process, and hot air will pass through the cylinder during rotation. To achieve the purpose of drying materials.

Auxiliary equipment for single cylinder dryer

Advantages of single drum dryer

1. Reasonable structure

The dryer adopts the design concept of reasonable partition, which makes the dispersing and throwing effect of the processed materials better, and the exchange frequency of materials and air is higher.

2. Good drying effect

The dryer adopts the co-current drying process of the material and the hot air flow, which maintains the original properties of the material; at the same time, the frequency conversion technology is used to control the rotation speed of the cylinder, optimize the contact time between the material and the hot flue gas, and improve the drying effect.

3. Simple and fast maintenance

On the one hand, the dryer adopts an automatic temperature monitoring system, which makes the system operation more intelligent and convenient; on the other hand, the structure of the dryer is optimized and improved, which effectively prolongs the service life of the dryer.

4. Low failure rate

The unique arch-breaking and rapping device of the dryer effectively solves the problems of the material sticking to the machine body and the lifting device, and the problems of material agglomeration and movement obstruction during the drying process. The failure rate is low, and the operation is stable and reliable.

Classification of dryers

Dryers can be divided into: industrial dryers, airflow dryers, slime dryers, fly ash dryers, rotary dryers, sludge dryers, rotary drums Dryer, quartz sand dryer and other dryer equipment.

The working process of the industrial dryer: First, the material is sent to the high silo through the bucket elevator, and the wet material in the silo slowly falls on the belt. The belt conveyor sends the material to the feed port of the dryer. It is placed in the combustion chamber at one end of the inlet of the dryer. The heat required for drying of the dryer is provided by the combustion chamber. There is a blower in the part, and the blower can blow the heat generated by the combustion chamber into the cylinder of the dryer by means of blowing. The dryer is placed horizontally on the rollers. The cylinder is inclined at an angle, which facilitates the material to slowly flow from the high inlet end to the low outlet end. In the process of the material flowing from one end to the other end, the material is in contact with the air, and is brought to a high place by the lifting plate on the cylinder wall and sprinkled down, and the hot air is in full contact with the material. achieve the purpose of drying.

Since the hot air will also take away a part of the material during the drying process, a cyclone dust collector is equipped at the tail of the dryer to collect the dust in the exhaust gas and reduce air pollution.

Direct heat transfer dryer: The material is in direct contact with the hot air after combustion, which is mostly used for material properties and material drying.

Indirect heat transfer dryer: The material is not in direct contact with the hot air, and the heat is transferred to the material through the cylinder wall. It is mostly used that the material cannot be in direct contact with the hot gas after combustion, or the properties of the material will change after contact. So use indirect heat transfer.

Downstream dryer: The flow direction of the material is the same as the flow direction of the hot air, so it is called a downstream dryer.

Counter-flow dryer: The flow direction of the material is opposite to that of the hot air, so it is called a counter-flow dryer.

TOP

TOP  Email

Email Phone

Phone Online

Online