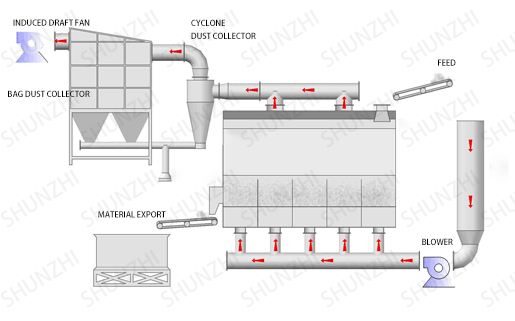

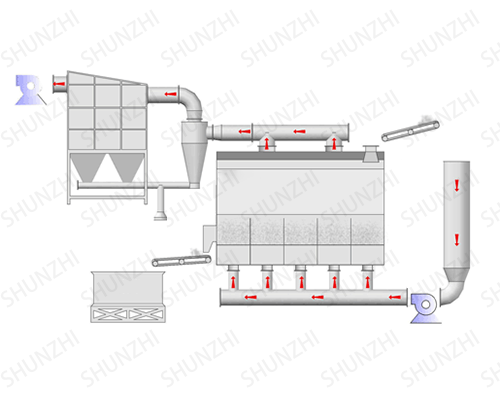

Process Flow Details

The mesh belt dryer is a drying equipment that uses steel mesh as a conveyor belt to carry materials for continuous drying. This machine can be used with other equipment. Can also be used alone. The equipment can be widely used in metallurgy, building materials, ceramics, fertilizer, chemical and other industries, and the mesh belt dryer is also an ideal equipment for drying food and vegetables.

The mesh belt dryer distributes the material to be processed on the conveyor belt through a suitable material spreading mechanism, such as a star distributor, swing belt, pulverizer or granulator, and the conveyor belt is composed of one or several heating units. Each heating unit is equipped with an air heating and circulation system, and each channel has one or several dehumidification systems. When the conveyor belt passes, the hot air passes through the conveyor belt from top to bottom or from bottom to top. material, so that the material can be dried evenly.

The main heating methods are electric heating, steam heating and hot air heating. The main principle is to spread the material evenly on the mesh belt. The mesh belt is made of 12-60 mesh steel mesh belt, which is dragged by the transmission device to move back and forth in the dryer. The drying machine is discharged from the moisture exhaust hole, so as to achieve the purpose of drying. The length of the box is composed of standard sections. In order to save space, the dryer can be made into a multi-layer type. 6-40m, effective width 0.6-3.0m.

TOP

TOP  Email

Email Phone

Phone Online

Online