Product Introduction

When the garbage incineration rotary kiln is in operation, the drum of the furnace body rotates continuously and slowly, and the high temperature resistant copy board on the inner wall is used to carry the garbage from the lower part of the cylinder to the upper part of the cylinder when it rolls, and then fall down by its own weight. Since the garbage rolls in the cylinder, it can be fully contacted with the air, and it will undergo a relatively complete combustion through three stages of ignition, combustion and burnout. The garbage is fed from one end of the drum, and the hot flue gas dries it and burns after reaching the ignition temperature. As the cylinder rolls, the garbage rolls and slides down until the ash is discharged from the outlet of the cylinder. When the water content of the garbage is too large, a grate can be added at the end of the cylinder to meet the burnout, and the flue gas discharged from the drum enters a vertical burnout chamber (secondary combustion chamber). The secondary air is sent into the combustion chamber, where the combustible components in the flue gas can be fully burned. The temperature of the burnout chamber is generally 1000-1200 °C. The equipment cost of the rotary kiln type waste burning device is low, and the power consumption of the plant is also less than that of other combustion methods. difficulty.

Performance Advantage

1: Social problems and environmental problems caused by garbage will be solved through a profit model

2: 98% reduction in waste volume, waste metal, cement fuel and raw materials are obtained from waste

3: Use cement to solidify residual heavy metals

4: Eliminate dioxins and other harmful substances

5: Eliminate gas emissions in the garbage chute

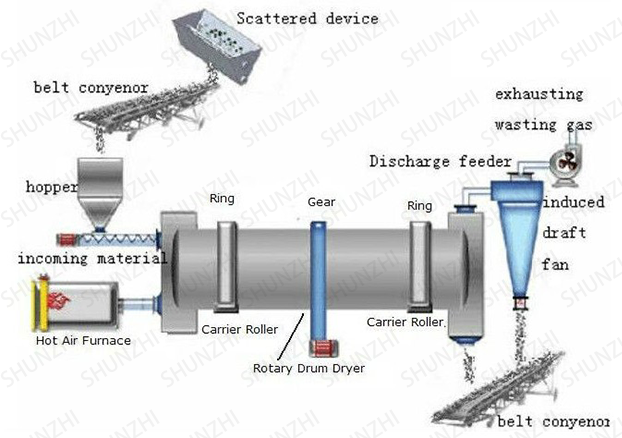

Equipment Pictures

Customer Site

Technical Parameter

| Model | Diameter (m) | Kiln body length (m) | Slope (%) | Capacity (t/d) | Speed (r/min) | Motor power (kw) | Weight (t) |

| φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149 |

| φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187 |

| φ2.5×54 | 2.5 | 54 | 3.5 | 204 | 0.48-1.45 | 55 | 196 |

| φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 1.10-1.52 | 55 | 198 |

| φ2.8×44 | 2.8 | 44 | 3.5 | 400 | 0.437-2.18 | 55 | 201 |

| φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210 |

| φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

| φ3.0×60 | 3 | 60 | 3.5 | 300 | 0.3-2 | 100 | 310 |

| φ3.2×50 | 3.2 | 50 | 3.5 | 1000 | 0.6-3 | 125 | 278 |

| φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

| φ3.5×54 | 3.5 | 54 | 4 | 1500 | 0.55-3.4 | 220 | 363 |

| φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

| φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

| φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

| φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.4-3.98 | 375 | 633 |

| φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

| φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 |

TOP

TOP  Email

Email Phone

Phone Online

Online