Product Introduction

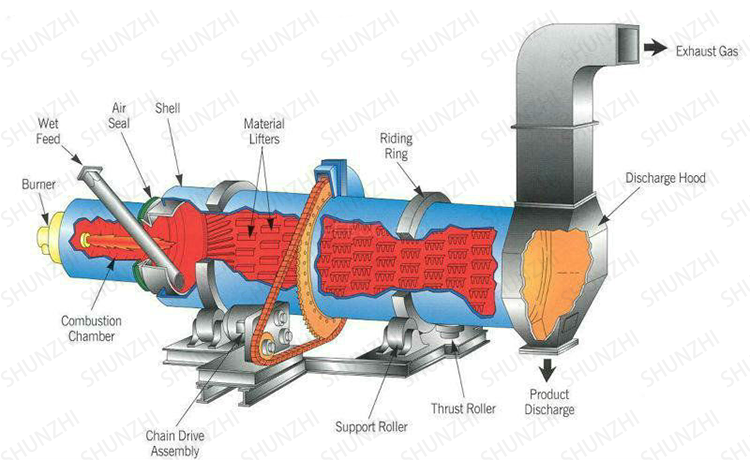

The cement rotary kiln is composed of a cylinder body, a transmission device, a support device, a retaining wheel supporting device, a kiln lining, a kiln tail seal, a kiln head and a fuel device. The cement rotary kiln operates under heavy load and alternating at a slow speed at high temperature. The maintenance of its accessories and the level of thermal system control are related to the safety and efficiency of the rotary kiln. The maintenance of the transmission device focuses on the lubrication of the equipment, the running state, the dynamic detection and the meshing accuracy of the large and small gears; the installation accuracy of the supporting device determines whether the rotary kiln can operate safely and reliably. During the operation, attention should be paid to the reasonable control of the bearing capacity distribution of the supporting rollers in each gear. , the arrangement of the supporting roller, the up and down pressure and time of the hydraulic stopper, the force of the supporting roller, and the gap between the tire and the backing plate. The quality of the sealing device directly affects the thermal system and operating cost of the rotary kiln. Strengthening the data collation and analysis of the daily maintenance of the rotary kiln is beneficial to the management of the equipment.

1. Preheating air: The heat treatment furnace of cement kiln equipment mostly adopts metal air preheater, and the residual heat of the air is below 427 °C. If the preheating temperature exceeds this temperature, the cost of the preheating system and the burner will increase significantly. Since the air preheating can supplement the heat brought into the furnace, the heat can be used to save fuel.

When the air preheating temperature is 427°C, not only about 15% of the recovered heat can be obtained to supplement the furnace, but also the loss of exhaust gas can be reduced from 50% to 35%, and the available heat in the furnace can be increased from 50% to 35%. 65%, and the fuel saving rate is around 23%.

2. Preheating workpieces in cement kiln equipment: The temperature of flue gas passing through the preheater should be maintained between 500-650 °C. This part of the heat of the flue gas can be used to preheat the workpieces to achieve the purpose of saving energy, but it should be considered to lead to Factors such as the cost of the flue gas pipeline and collection area in the preheating area, the cost of the preheating area itself and the additional space. Whether it is economical and reasonable to use the waste heat of flue gas to preheat the workpiece should be analyzed according to the actual conditions.

Performance Advantage

1. The kiln cylinder is a heated rotating part, which is made of dead steel plate by coil welding. The cylinder is supported on the support device of the 2nd to 7th block sliding bearing through the tire belt, and one or several blocks of the support device are provided with Mechanical or hydraulic stopper to control the axial movement of the cylinder.

2. The transmission device makes the cylinder rotate at the required speed through the ring gear set in the middle of the cylinder.

3. Due to the needs of installation and maintenance, the larger kiln is equipped with an auxiliary transmission device that makes the cylinder rotate at a very low speed.

4. In order to prevent cold air from entering and flue gas dust overflowing the cylinder, reliable kiln tail and kiln head sealing devices are installed at the feeding end (tail) and the discharging end (head) of the cylinder.

Equipment Pictures

Customer Site

Technical Parameter

| Model | Diameter (m) | Kiln body length (m) | Slope (%) | Capacity (t/d) | Speed (r/min) | Motor power (kw) | Weight (t) |

| φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149 |

| φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187 |

| φ2.5×54 | 2.5 | 54 | 3.5 | 204 | 0.48-1.45 | 55 | 196 |

| φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 1.10-1.52 | 55 | 198 |

| φ2.8×44 | 2.8 | 44 | 3.5 | 400 | 0.437-2.18 | 55 | 201 |

| φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210 |

| φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

| φ3.0×60 | 3 | 60 | 3.5 | 300 | 0.3-2 | 100 | 310 |

| φ3.2×50 | 3.2 | 50 | 3.5 | 1000 | 0.6-3 | 125 | 278 |

| φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

| φ3.5×54 | 3.5 | 54 | 4 | 1500 | 0.55-3.4 | 220 | 363 |

| φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

| φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

| φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

| φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.4-3.98 | 375 | 633 |

| φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

| φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 |

TOP

TOP  Email

Email Phone

Phone Online

Online