Product Introduction

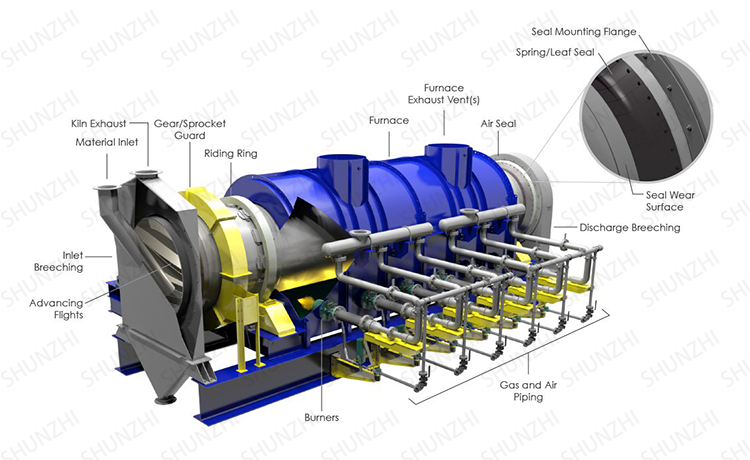

Mica ore rotary kiln is composed of cylinder body, supporting device, supporting device with blocking wheel, transmission device, movable kiln head, kiln tail sealing device, coal injection pipe device and other components. The kiln body of the rotary kiln is inclined to a certain level. The kiln body is supported by the supporting roller device, and has a retaining wheel device to control the up and down movement of the kiln body. In addition to the main drive, the transmission system is also equipped with a main power supply that can still enable the kiln body to rotate to prevent the kiln body from bending. Deformed auxiliary transmission device, kiln head and kiln tail sealing device ensure the reliability of sealing.

The mica ore rotary kiln uses a dual-pressure system to make the rotary kiln calcination system work under normal conditions, which greatly saves energy and reduces production costs. Positive pressure is maintained, while the dual pressure system primarily controls primary and secondary air accuracy. On the rotary kiln top of the rotary kiln equipment, the high-temperature exhaust gas in the kiln is transferred to the area above the calcining zone of the rotary kiln system by the moving device of the operation regulator to heat the temperature. The air volume adjustment range is 10%-80%.

Performance Advantage

1. The working reliability of the equipment is very high, and the performance is very good, which lays a favorable foundation for improving the working efficiency of the equipment.

2. From the perspective of technical parameters, this equipment uses dual motors to work, and excellent motors can improve the production capacity of the equipment, so its output can meet user standards.

3. Compared with the traditional equipment, the structure of the equipment is very reasonable, and its stability is very strong, so there will be no failure in the production process, which is one of the main reasons for its high output.

Equipment Pictures

Customer Site

Technical Parameter

| Model | Diameter (m) | Kiln body length (m) | Slope (%) | Capacity (t/d) | Speed (r/min) | Motor power (kw) | Weight (t) |

| φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149 |

| φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187 |

| φ2.5×54 | 2.5 | 54 | 3.5 | 204 | 0.48-1.45 | 55 | 196 |

| φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 1.10-1.52 | 55 | 198 |

| φ2.8×44 | 2.8 | 44 | 3.5 | 400 | 0.437-2.18 | 55 | 201 |

| φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210 |

| φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

| φ3.0×60 | 3 | 60 | 3.5 | 300 | 0.3-2 | 100 | 310 |

| φ3.2×50 | 3.2 | 50 | 3.5 | 1000 | 0.6-3 | 125 | 278 |

| φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

| φ3.5×54 | 3.5 | 54 | 4 | 1500 | 0.55-3.4 | 220 | 363 |

| φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

| φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

| φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

| φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.4-3.98 | 375 | 633 |

| φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

| φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 |

TOP

TOP  Email

Email Phone

Phone Online

Online