Product Introduction

The zinc oxide rotary kiln process is mainly to pulverize the zinc charge and coking coal into particles smaller than 40 mesh, mix the zinc charge and coking coal in a ratio of 1:0.30 to 0.35 to obtain a mixture, and then make the mixture into an effective diameter of 8-15mm granular mixture, and finally put the granular mixture into the rotary kiln for smelting. When the zinc oxide ore or zinc-containing industrial slag with a zinc content of 15% to 25% is smelted to produce zinc oxide, it can save a lot of money. Coke or coal, zinc oxide obtained by smelting has high productivity, good product quality and small nodule amount.

Zinc oxide rotary kiln fully respects the simplicity of operation in the design and structure, and the performance of the equipment can be fully utilized in production. Customers and friends are very fond of this product, and they rush to our company to order products.

Performance Advantage

1. Cost saving: Our company's zinc oxide rotary kiln can greatly save the use of coke and coal when calcining those zinc oxide ores and industrial slag containing zinc, which greatly saves the fuel demand for customers. production cost.

2. It has good safety protection measures: the zinc oxide rotary kiln equipment is also very well done in terms of safety. Scanning by the infrared scanner just introduced from abroad can always observe the situation in the kiln, production It helps staff to take protective measures in advance.

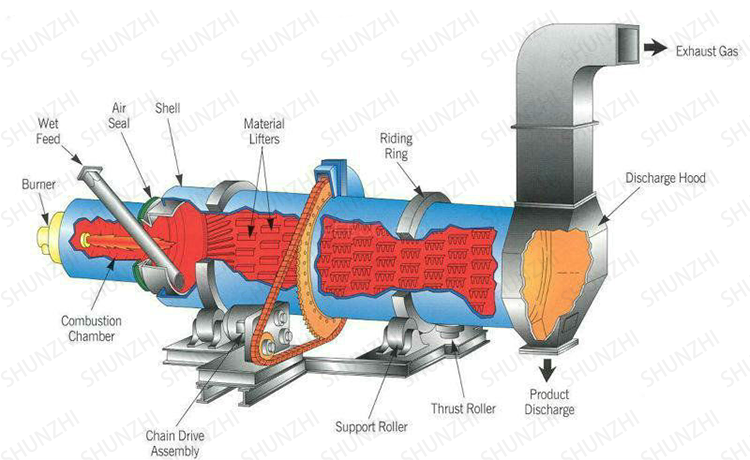

Equipment Pictures

Customer Site

Technical Parameter

| Model | Diameter (m) | Kiln body length (m) | Slope (%) | Capacity (t/d) | Speed (r/min) | Motor power (kw) | Weight (t) |

| φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149 |

| φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187 |

| φ2.5×54 | 2.5 | 54 | 3.5 | 204 | 0.48-1.45 | 55 | 196 |

| φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 1.10-1.52 | 55 | 198 |

| φ2.8×44 | 2.8 | 44 | 3.5 | 400 | 0.437-2.18 | 55 | 201 |

| φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210 |

| φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

| φ3.0×60 | 3 | 60 | 3.5 | 300 | 0.3-2 | 100 | 310 |

| φ3.2×50 | 3.2 | 50 | 3.5 | 1000 | 0.6-3 | 125 | 278 |

| φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

| φ3.5×54 | 3.5 | 54 | 4 | 1500 | 0.55-3.4 | 220 | 363 |

| φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

| φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

| φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

| φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.4-3.98 | 375 | 633 |

| φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

| φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 |

TOP

TOP  Email

Email Phone

Phone Online

Online