Product Introduction

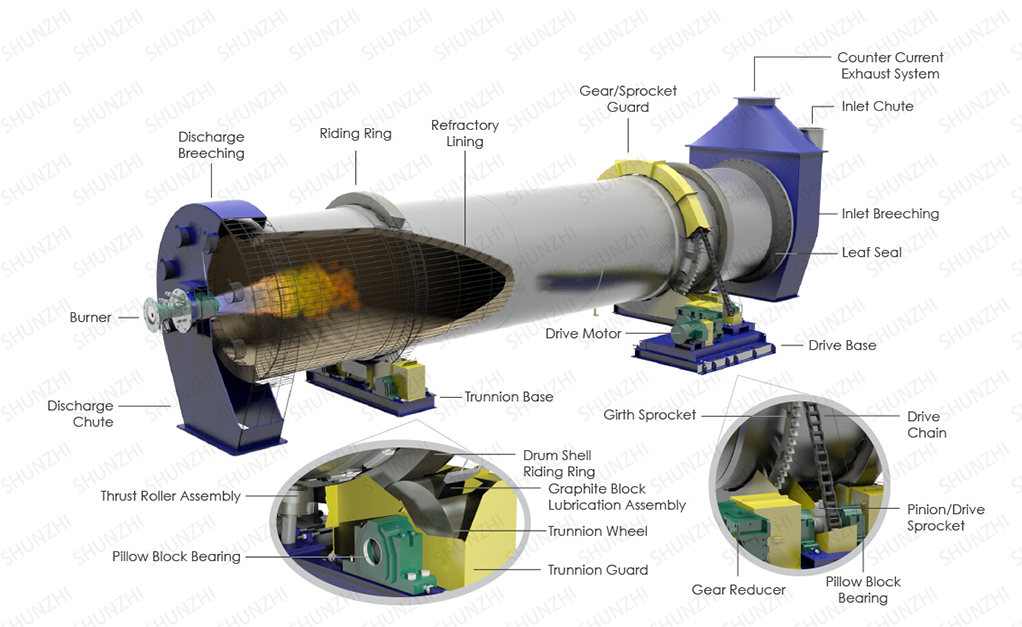

Calcium aluminate rotary kiln is mainly composed of shell, supporting equipment, thrust roller, mobile kiln head, sealing device at the rear of the kiln tail, combustion device and other simple structures, and the working process is easy to control. The main components of calcium aluminate rotary kiln are composed of cylinder, supporting device, supporting device with blocking wheel, transmission device, movable kiln head, kiln tail sealing device, combustion device, etc. The calcium aluminate rotary kiln has a simple structure and reliable operation. , the production process is easy to control and so on.

Work Process

The raw ore is directly fed into the kiln tail of the calcium aluminate rotary kiln from the storage through electronic belt weighing scales, belt conveyors, stabilizing bins and air lock valves, and only stabilizing bins are set at the kiln tail to reduce investment. The ore enters the calcium aluminate rotary kiln to be heated first, the raw ore moves in the reverse direction with the hot air flow in the kiln, and the raw ore is heated to the reduction temperature in the heating zone and then enters the reduction zone. The temperature of the flame center in the reduction zone is controlled at about 1000°C, and the temperature of the hot atmosphere in the reduction zone is controlled at about 700°C to react and reduce with the reducing gas. Then it enters the cooling zone and meets the incoming gas, the gas is preheated, and the ore is cooled and discharged out of the calcium aluminate rotary kiln.

Performance Advantage

1. The calcium aluminate rotary kiln has the characteristics of simple structure, reliable operation and easy control of the production process.

2. Calcium aluminate rotary kiln can be widely used in chemical industry, environmental protection, sewage treatment and other fields.

3. The new technology calcium aluminate rotary kiln overcomes the problem of high calorific value and short flame combustion of coke oven gas, which can make full use of the remaining coke oven gas.

4. Calcium aluminate rotary kiln has very good energy saving, environmental protection and efficiency enhancement effects on small and medium iron and steel enterprises, coking enterprises, calcium carbide enterprises, and refractory materials industry.

Equipment Pictures

Customer Site

Technical Parameter

| Model | Diameter (m) | Kiln body length (m) | Slope (%) | Capacity (t/d) | Speed (r/min) | Motor power (kw) | Weight (t) |

| φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149 |

| φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187 |

| φ2.5×54 | 2.5 | 54 | 3.5 | 204 | 0.48-1.45 | 55 | 196 |

| φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 1.10-1.52 | 55 | 198 |

| φ2.8×44 | 2.8 | 44 | 3.5 | 400 | 0.437-2.18 | 55 | 201 |

| φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210 |

| φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

| φ3.0×60 | 3 | 60 | 3.5 | 300 | 0.3-2 | 100 | 310 |

| φ3.2×50 | 3.2 | 50 | 3.5 | 1000 | 0.6-3 | 125 | 278 |

| φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

| φ3.5×54 | 3.5 | 54 | 4 | 1500 | 0.55-3.4 | 220 | 363 |

| φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

| φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

| φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

| φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.4-3.98 | 375 | 633 |

| φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

| φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 |

TOP

TOP  Email

Email Phone

Phone Online

Online