Product Introduction

When the rotary kiln is in normal operation, the main drive motor transmits power to the open gear device through the main reducer to drive the rotary kiln. The material enters the kiln from the kiln tail (the high end of the cylinder) for calcination. Due to the inclination and slow rotation of the cylinder, the material rolls in the circumferential direction and moves in the axial direction (from the high end to the low end), and the raw clinker enters the cooler for cooling through the kiln head cover. The fuel is injected into the kiln from the kiln head, and the waste gas produced by the combustion is exchanged with the material, and then exported from the kiln tail.

In addition to calcining cement clinker, cement kiln is also used for calcining clay, limestone and slag drying. In non-ferrous and ferrous metallurgy, iron, aluminum, copper, zinc, tin, nickel, tungsten, chromium, file and other metals use rotary kiln as smelting equipment to sinter and roast ores, concentrates and intermediates. For example: it is used in aluminum production to calcine aluminum hydroxide into alumina; it is used in ironmaking to produce pellets for blast furnace ironmaking; foreign "SL/RN method" and "Krupp method" use it to treat iron ore. Direct reduction is carried out; chlorination volatilization roasting method uses it to extract tin and lead. In the process of beneficiation, the rotary kiln is used to magnetize and roast the lean iron ore, so that the original weak magnetism of the ore is changed to strong magnetism, which is beneficial to the magnetic separation. In the chemical industry, rotary kilns are used to produce soda, calcine phosphate fertilizers, barium sulfide, etc. This method has the advantages of low energy consumption, low electricity consumption, no need for sulfuric acid, and the availability of medium and low grade phosphate rock, and it was quickly popularized.

Performance Advantage

1. Smart Security

Based on mine intelligent beneficiation technology, we are committed to becoming a supplier of integrated solutions for intelligent mines; intelligent manufacturing, safe production;

2. Energy saving and high efficiency

Develop high-efficiency and energy-saving large-scale mine complete sets of equipment, which can save 40% energy than common mineral processing equipment and have high mineral processing efficiency;

3. Dust removal and environmental protection

It effectively reduces the damage of mine dust to the human body, improves the work efficiency that is slowed down by the influence of dust, and meets the requirements of environmental protection production;

4. Beautiful and durable

The shape is sleek and novel, the color is beautiful, and the owner can choose freely; the running noise is low, and the equipment has high wear resistance;

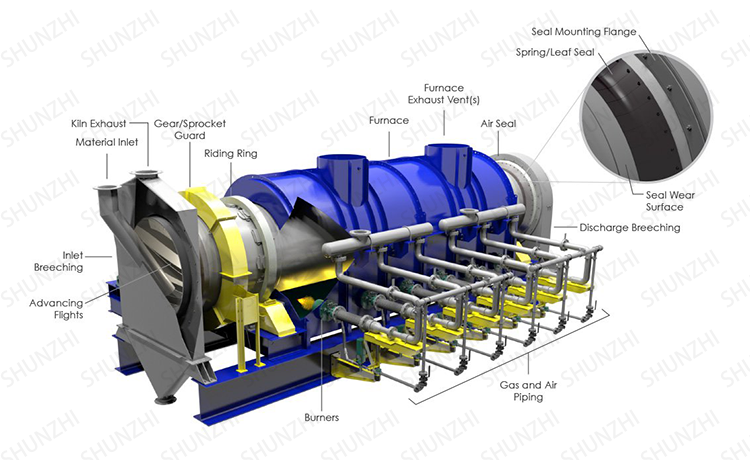

Equipment Pictures

Customer Site

Technical Parameter

| Model | Diameter (m) | Kiln body length (m) | Slope (%) | Capacity (t/d) | Speed (r/min) | Motor power (kw) | Weight (t) |

| φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149 |

| φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187 |

| φ2.5×54 | 2.5 | 54 | 3.5 | 204 | 0.48-1.45 | 55 | 196 |

| φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 1.10-1.52 | 55 | 198 |

| φ2.8×44 | 2.8 | 44 | 3.5 | 400 | 0.437-2.18 | 55 | 201 |

| φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210 |

| φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

| φ3.0×60 | 3 | 60 | 3.5 | 300 | 0.3-2 | 100 | 310 |

| φ3.2×50 | 3.2 | 50 | 3.5 | 1000 | 0.6-3 | 125 | 278 |

| φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

| φ3.5×54 | 3.5 | 54 | 4 | 1500 | 0.55-3.4 | 220 | 363 |

| φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

| φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

| φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

| φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.4-3.98 | 375 | 633 |

| φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

| φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 |

TOP

TOP  Email

Email Phone

Phone Online

Online