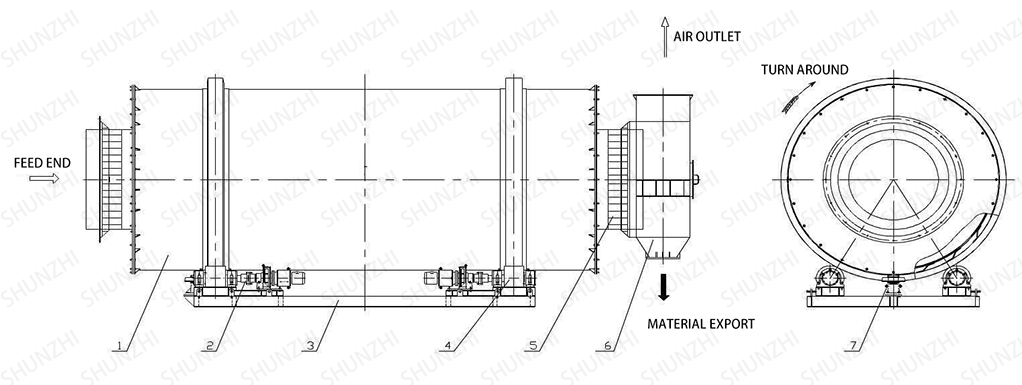

Product Introduction

The structure of the three-cylinder rotary dryer is composed of an outer cylinder, a middle cylinder, an inner cylinder, a tire belt, a supporting wheel, a reducer motor, a supporting base, etc. The rotary device of the dryer is composed of three concentric cylinders with different diameters. The rotary parts are placed horizontally on the four supporting rollers at both ends through the belts at both ends, and there are sealing devices at both ends. The feed end is provided with a fuel (or steam, coal, etc.) hot blast stove device; the discharge end is provided with a dust cover and a discharge device, and the dust cover is connected to the dust removal equipment through a pipeline. Dust removal equipment, feeding equipment and conveying equipment should be designed separately according to the user's process conditions and usage requirements.

It is sent to the hopper by a belt conveyor or a bucket elevator, and then enters the feeding end through the feeding pipeline through the feeding machine of the hopper. The inclination of the feeding pipeline should be greater than the natural inclination of the material, so that the material can flow into the mine dryer smoothly. The dryer cylinder is a rotating cylinder that is slightly inclined to the horizontal. The material is added from the higher end, the heat carrier enters from the low end, and is in countercurrent contact with the material, and some heat carrier and material flow into the cylinder together. With the rotation of the cylinder, the material runs to the bottom end by gravity. When the wet material moves forward in the cylinder, it is directly or indirectly fed by the heat carrier, so that the wet material can be dried, and then sent out through a belt conveyor or a screw conveyor at the discharge end.

Performance Advantage

1. The barrel is self-insulated, and the thermal efficiency is as high as 95%.

2. Compared with the single-cylinder dryer, the length of the whole machine is shortened by 50%, and the land investment is reduced by about 50%.

3. The cylinder body is welded with heat-resistant and wear-resistant metal steel plate, which has long service life and convenient maintenance.

4. High thermal efficiency, the temperature of outer copper and iron is ≤60°C (the temperature of the outer body of the single-cylinder dryer is as high as 150°C).

5. The outlet temperature is low, the dust removal equipment has a long service time, and it can be directly matched with the air box pulse bag filter.

6. There is no large or small gear, the tug is used to rotate, and the whole machine runs horizontally, which makes the system more simple and reasonable.

7. The hot blast stove can be equipped with a boiling stove (also oil and gas stoves can be used), which can dry materials below 20mm.

8. The user can adjust the required moisture index according to the requirements.

Equipment Pictures

Customer Site

Technical Parameter

| Model | External Shell Diameter(m) | Length(m) | Volume(m) | Revolution Speed(r/min) | Highest Inlet Air Temperature(℃) | Capacity(t/h) | Power(kw) |

| 2*4.5m | 2 | 4.5 | 14.13 | 4—10 | 700—750℃ | 13—18 | 5.5*2 |

| 2.2*5m | 2.2 | 5 | 18.99 | 4—10 | 700—750℃ | 15—23 | 7.5*2 |

| 2.5*6m | 2.5 | 6 | 29.43 | 4—10 | 700—750℃ | 20—28 | 5.5*4 |

| 2.7*6.5m | 2.7 | 6.5 | 37.19 | 4—10 | 700—750℃ | 24—33 | 7.5*4 |

| 3.0*6.5m | 3 | 6.5 | 45.92 | 4—10 | 700—750℃ | 35—40 | 11*4 |

| 3.2*7m | 3.2 | 7 | 56.27 | 4—10 | 700—750℃ | 40—60 | 15*4 |

| 3.6*8m | 3.6 | 8 | 81.39 | 4—10 | 700—750℃ | 55—75 | 18.5*4 |

| 4.2*8m | 4.2 | 8 | 110.78 | 4—10 | 700—750℃ | 70—120 | 22*4 |

TOP

TOP  Email

Email Phone

Phone Online

Online