Product Introduction

The fly ash dryer is a single-cylinder rotary dryer. When working, the wet material is sent to the hopper by a belt conveyor or a bucket elevator, and then enters the feeding end through the feeding pipe through the feeding machine of the hopper. The inclination of the feeding pipeline should be greater than the natural inclination of the material, so that the material can flow into the dry pulverized coal dryer smoothly. The pulverized coal dryer cylinder is a rotating cylinder slightly inclined to the horizontal line. The material is added from the higher end of the fly ash dryer, and the heat carrier enters from the lower end, which is in countercurrent contact with the material, and the heat carrier and the material flow into the cylinder together. With the rotating material of the fly ash dryer cylinder, the material runs to the bottom end by gravity. During the forward movement of the wet material in the cylinder of the fly ash dryer, the heat supplied by the heat carrier is directly or indirectly obtained, so that the wet material is dried, and then sent out through a belt conveyor or a screw conveyor at the discharge end. A copy board is installed on the inner wall of the fly ash dryer cylinder. Its function is to copy and sprinkle the material, so that the contact surface between the material and the airflow increases, so as to improve the drying rate and promote the advancement of the material. Heating medium is generally divided into hot air, flue gas and so on. After the heat carrier passes through the pulverized coal dryer, a cyclone dust collector is generally required to capture the materials in the gas. If it is necessary to further reduce the dust content of the exhaust gas, it should also be discharged after passing through a bag filter or a wet filter.

Performance Advantage

1. Fast drying and high efficiency. The fly ash/slag dryer has the characteristics of high temperature resistance and can use high temperature hot air to dry the material.

2. Wide range of dry raw materials. The machine adopts the co-current drying process of material and hot air flow, and has a wide range of applications. It is suitable for drying various raw materials such as coal, fly ash, iron powder, etc. It is also suitable for drying various bulk materials in metallurgy, chemical industry and other departments.

3. Large processing capacity and wide range of heat sources. The fly ash dryer has large processing capacity, low fuel consumption and low drying cost. The heat source can be selected from coal, natural gas, biomass fuel, electricity, etc.

4. Strong expansion ability. Designed with production margins in mind, even a small increase in production requires no equipment replacement.

5. Low wear and long life. The equipment adopts a self-aligning tug structure, and the tug and the rolling ring cooperate well, which greatly reduces the wear and power consumption.

6. Advanced design and high degree of automation. The specially designed retaining wheel structure greatly reduces the horizontal thrust caused by the tilting of the equipment, and has strong anti-overload capability, stable operation of the cylinder and high reliability.

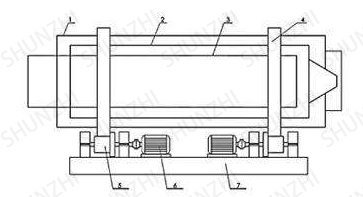

Equipment Pictures

Customer Site

Technical Parameter

| Model | External Shell Diameter(m) | Length(m) | Volume(m) | Revolution Speed(r/min) | Highest Inlet Air Temperature(℃) | Capacity(t/h) | Power(kw) |

| 2*4.5m | 2 | 4.5 | 14.13 | 4—10 | 700—750℃ | 13—18 | 5.5*2 |

| 2.2*5m | 2.2 | 5 | 18.99 | 4—10 | 700—750℃ | 15—23 | 7.5*2 |

| 2.5*6m | 2.5 | 6 | 29.43 | 4—10 | 700—750℃ | 20—28 | 5.5*4 |

| 2.7*6.5m | 2.7 | 6.5 | 37.19 | 4—10 | 700—750℃ | 24—33 | 7.5*4 |

| 3.0*6.5m | 3 | 6.5 | 45.92 | 4—10 | 700—750℃ | 35—40 | 11*4 |

| 3.2*7m | 3.2 | 7 | 56.27 | 4—10 | 700—750℃ | 40—60 | 15*4 |

| 3.6*8m | 3.6 | 8 | 81.39 | 4—10 | 700—750℃ | 55—75 | 18.5*4 |

| 4.2*8m | 4.2 | 8 | 110.78 | 4—10 | 700—750℃ | 70—120 | 22*4 |

TOP

TOP  Email

Email Phone

Phone Online

Online