Product Introduction

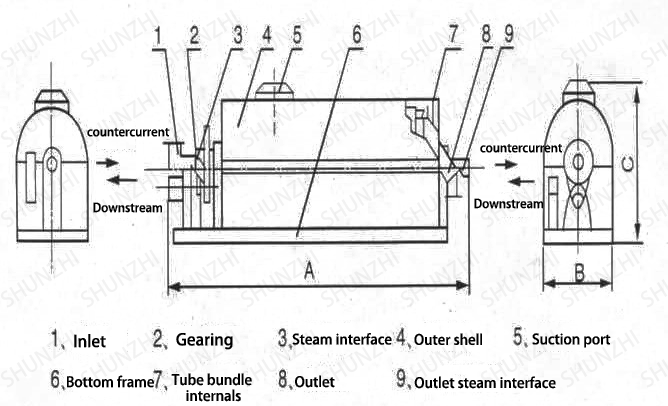

The rotor of the tube bundle dryer consists of a hollow shaft at both ends, a head and hundreds of tubes, in addition to the main motor, deceleration system, regulating valve, metal hose, rotary joint, exhaust and dust removal system, etc.

The material is sent into the dryer through the screw conveyor, and is continuously picked up by the copy board on the outer edge of the tube bundle and distributed evenly on the cross section of the tube bundle, while pushing the material forward along the dryer shaft. In this process, the material and the internal heat of the dryer carry out sufficient heat exchange, so that the internal moisture is continuously evaporated. Finally, the dried material is discharged through the discharge screw.

Performance Advantage

Material drying flexibility is large (the drying time can be adjusted according to different material properties and moisture requirements), continuous production (high degree of automation), and intermittent operation (suitable for special production processes); the material is in a closed state under negative pressure The cavity is dry, the working environment is clean, pollution-free, and low noise.

Equipment Pictures

Customer Site

Technical Parameter

| Materials | Germ | Corn fiber | Corn protein |

| Inlet water content | 55% | 60% | 45% |

| Outlet water content | 3~5% | 10~12% | 12~13% |

| Drying intensity (evaporation kg water/ m2) | 2.5~3 | 4.8 | 4.7 |

| Model | Outline dimension | Main power(kw) | Weight (T) |

| GZG60 | 6100*1600*2160 | 5.5 | 9 |

| GZG100 | 7800*1900*2460 | 7.5 | 13.5 |

| GZG150 | 7100*2200*2750 | 11 | 19.5 |

| GZG300 | 8800*2460*3180 | 18.5 | 26.5 |

| GZG500 | 10980*2900*4000 | 37 | 50 |

| GZG650 | 11190*3200*4300 | 55 | 67 |

| GZG1000 | 11800*3660*4770 | 110 | 91 |

TOP

TOP  Email

Email Phone

Phone Online

Online