Product Introduction

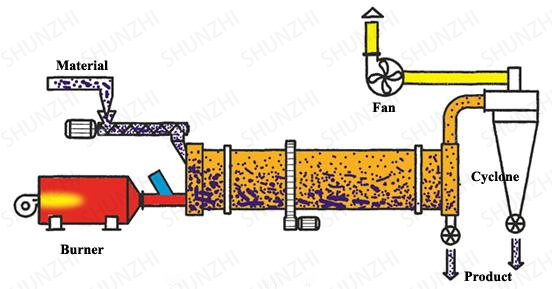

The complete set of powder dryer equipment is mainly composed of drum crushing dryer, combustion furnace, feeding screw, discharging screw, conveying pipeline, dust collector, air shutter, induced draft fan, control cabinet, etc.

The mineral powder is directly fed into the drum crushing dryer by the feeding screw, and is repeatedly picked up and scattered by the copying plate on the inner wall of the drum. After being dispersed by the crushing device, the material fully contacts with the high temperature medium under negative pressure to complete the heat and mass transfer. process. Due to the inclination angle of the drum and the effect of the divided air, the material moves slowly from the feed end, and is discharged by the discharge screw after drying. The tail gas is discharged into the atmosphere after being dusted by the dust collector.

Performance Advantage

1. The drying process of the mineral powder dryer is advanced, adopting high temperature and rapid drying process, with large heat transfer coefficient, high thermal efficiency and high drying strength.

2. The combination of high-speed stirring drying and airflow drying can fully disperse the viscous materials, greatly increase the contact area between the materials and the heating medium, and facilitate the drying process.

3. A special scraping device is used in the mineral powder dryer to avoid the phenomenon of material sticking to the wall.

4. Wide application range, simple operation, small maintenance amount and stable product quality.

5. Mineral powder dryer machine is specially designed for drying mineral powder, with variable angle of rotating blades and adjustable rotating shaft speed.

6. The upper part of the ore powder dryer is equipped with a wet material reflux layer, and the air dryer is equipped with special agitators.

Equipment Pictures

Customer Site

Technical Parameter

| Specification(m) | Cylinder volume | Capacity | Installation slope | Max intake air temperature | Main motor | Total weight |

| (Diameter x Length) | (m³) | (t/h) | (%) | (℃) | (kw) | (t) |

| Φ1.2×8.0 | 9 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |

| Indirect heat transfer dryer | ||||||||

| Cylinder diameter × Cylinder length | Inner diameter of outer cylinder (mm) | Inner cylinder inner diameter (mm) | Cylinder length (m) | Cylinder volume (m³) | Cylinder slope | Lifting plate type | Maximum intake air temperature (℃) | Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | lift type | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | lift type | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.1 | 3-5% | lift type | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 | ||||||

TOP

TOP  Email

Email Phone

Phone Online

Online