Product Introduction

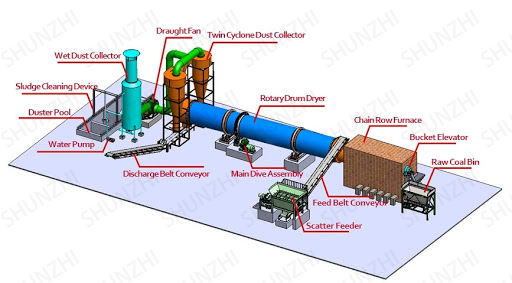

The drying equipment is mainly composed of rotating body, lifting plate, transmission device, supporting device and sealing ring.(Industrial dryers are generally equipped with hoppers, belt conveyors, rotating cylinders, screw conveyors, copy plates, cyclones and other equipment)

The material to be dried enters the cylinder from the feed box and the feed, and is then pushed to the back end by the spiral plate. Due to the inclined placement of the dryer, on the one hand, the material flows to the back end under the action of gravity and rotation, on the other hand, the material is repeatedly picked up by the copy board, brought to the upper end and then continuously scattered down, so that the material forms a uniform curtain in the cylinder. The curtain fully exchanges heat with the hot air flow in the cylinder. As the material is repeatedly scattered, the moisture contained in it is gradually dried, so as to achieve the purpose of drying.

Performance Advantage

1. Strong anti-overload ability, large processing capacity, low fuel consumption and low drying cost.

2. The downstream drying method is adopted. The flue gas and wet materials enter the dryer from the same side. High-temperature flue gas can be used to obtain high evaporation intensity. The outlet temperature of the dryer is low and the thermal efficiency is high.

3. Adopting dispersing device, feeding device, discharging device, cyclone dust removal device, so as to prevent the drying machine feeding jam, discontinuity, unevenness and return of materials, and reduce the load of the dust removal system.

4. The dryer adopts the "adjustable supporting roller device", so that the matching of the supporting roller and the rolling ring is always in linear contact, thus greatly reducing the wear and power loss.

5. It adopts open gear transmission, which has the characteristics of reasonable structure, simple operation, long service life, high efficiency and convenient maintenance.

In the drying production process, most of the downstream operations are performed, and its main features are:

1. At the hot end of the dryer, the temperature difference between the material and the hot gas is large, the heat exchange process is rapid, a large amount of water is easy to evaporate, and it is suitable for materials with higher initial moisture.

2. After the viscous material enters the dryer, because the surface moisture is easy to evaporate, the adhesion can be reduced, which is conducive to the movement of the material. When used for drying wet coal, it can avoid direct contact of high temperature gas with dry coal to cause fire.

3. The low negative pressure at the hot end of the downstream operation can reduce the amount of air leakage into the drying and help stabilize the temperature and flow rate of the hot air in the dryer.

4. Feeding and coal supply are set at the same hot end as the dryer, so the layout of the workshop is more convenient.

5. The discharge temperature of the downstream dryer is low, and it can generally be conveyed by a belt conveyor.

Equipment Pictures

Customer Site

Technical Parameter

| Specification(m) | Cylinder volume | Capacity | Installation slope | Max intake air temperature | Main motor | Total weight |

| (Diameter x Length) | (m³) | (t/h) | (%) | (℃) | (kw) | (t) |

| Φ1.2×8.0 | 9 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |

| Indirect heat transfer dryer | ||||||||

| Cylinder diameter × Cylinder length | Inner diameter of outer cylinder (mm) | Inner cylinder inner diameter (mm) | Cylinder length (m) | Cylinder volume (m³) | Cylinder slope | Lifting plate type | Maximum intake air temperature (℃) | Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | lift type | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | lift type | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.1 | 3-5% | lift type | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 | ||||||

TOP

TOP  Email

Email Phone

Phone Online

Online