Product Introduction

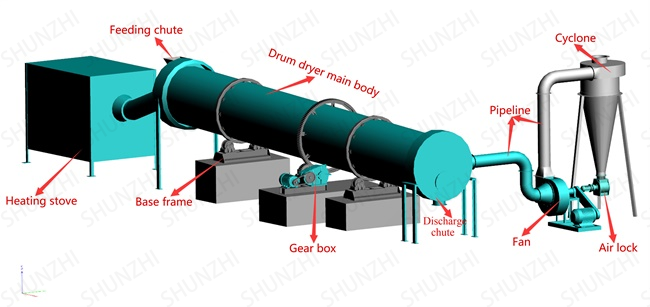

The lees dryer is mainly composed of cylinder, gear, stop roller, idler, feed chute, front roller ring, rear roller ring, discharge, pinion, motor, hot air duct, lifting plate, reducer, furnace body And other structural composition.

When the vinasse dryer is working, the vinasse is sent to the hopper by the conveying equipment and fed into the feeding end of the vinasse dryer by the feeder, and enters the barrel smoothly through the inclined feeding pipe. The cylinder is slowly rotating during the working process, and is inclined at a certain angle with the horizontal line. The distiller’s lees enters the barrel from a high place and slowly travels towards the lower end under the action of gravity. At the same time, the heat carrier is introduced from the low end and continuously impacts to the higher place, making reverse contact with the distiller’s grain materials, and the two are in contact with each other. In the process, the drying of the distiller's grains is completed. In addition, there is a copying plate in the cylinder, which can continuously pick up and spill the distiller's grains, which greatly increases the contact area between the distiller's grains and the heating medium, and improves the drying rate.

Performance Advantage

1. Novel structure and easy operation: The equipment is not only very simple in appearance and structure, but also relatively simple in internal structure. Installation, operation and maintenance are very simple and convenient.

2. Stable operation and long service life: The equipment adopts a unique "zero horizontal thrust" method, which makes the cylinder more stable and reliable during operation, and the main components of the equipment are made of materials, and the quality is very reliable. The service life is 3-5 times that of ordinary dryers.

3. High efficiency and good drying effect: The equipment is equipped with a combined lifting device, which has high thermal efficiency and very high drying efficiency.

4. High output, green and environmental protection: The volume of the barrel of the equipment is designed to be relatively large, and the content of distiller's grains that can be accommodated is high, so the output is also very high. In addition, the equipment is equipped with a dust removal device, which can completely avoid dust pollution during operation and is more environmentally friendly.

5. Energy saving and consumption reduction, low cost: The equipment has very low heat energy loss during the drying process of the distiller’s grains, which is more energy-saving and consumption-reducing. It can save nearly 50,000 yuan in cost for the processing plant every year, and the production cost is quite low. .

Equipment Pictures

Customer Site

Technical Parameter

| Specification(m) | Cylinder volume | Capacity | Installation slope | Max intake air temperature | Main motor | Total weight |

| (Diameter x Length) | (m³) | (t/h) | (%) | (℃) | (kw) | (t) |

| Φ1.2×8.0 | 9 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |

| Indirect heat transfer dryer | ||||||||

| Cylinder diameter × Cylinder length | Inner diameter of outer cylinder (mm) | Inner cylinder inner diameter (mm) | Cylinder length (m) | Cylinder volume (m³) | Cylinder slope | Lifting plate type | Maximum intake air temperature (℃) | Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | lift type | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | lift type | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.1 | 3-5% | lift type | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 | ||||||

TOP

TOP  Email

Email Phone

Phone Online

Online