Product Introduction

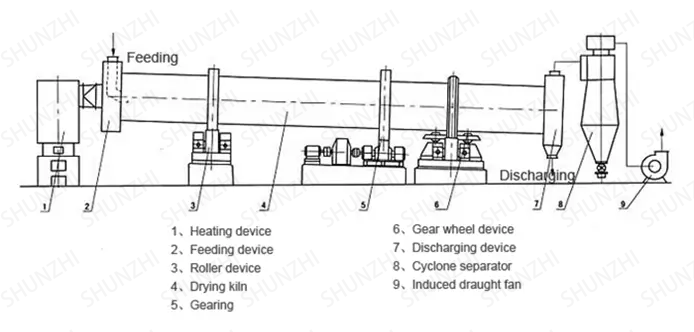

The limestone dryer is mainly composed of cylinder, gear, motor, reducer, feed chute, hot air duct, baffle roller and other components.

When the limestone dryer is in operation, the limestone is transported to the hopper by the belt conveyor or elevator, and then the limestone is uniformly and continuously sent to the feeding end by the vibrating feeder. The drying cylinder of the equipment is clamped to the horizontal line. Angle, limestone enters from a high place, the heating medium and limestone enter the cylinder in the same direction or in the reverse direction. The limestone in the cylinder directly or indirectly gets the heat from the heating medium, and the wet limestone can be dried and dried under the action of the heating medium. The latter limestone is sent out under the action of belt conveyor or screw conveyor. If the user needs to further reduce the dust content in the exhaust gas, the dried limestone should also be discharged after passing through a bag filter or a wet dust collector.

Performance Advantage

1. Energy saving

Compared with traditional limestone dryers, the limestone dryer can save energy by 50% and increase the output by 40%, which can greatly improve the user's production and increase its benefits. The length of the equipment is shortened by 30%, which is beneficial to the construction of production sites and construction costs. There has also been a decline.

2. Long service life

The equipment produced by it uses alloy steel plates with strong heat resistance and wear resistance. The wear resistance is more than 4 times that of ordinary steel plates. The body wear is small, and the outlet temperature of the equipment is low, which effectively increases the service life of the dust removal equipment. It saves more than 60,000 to 100,000 yuan in production costs, and effectively reduces the user's production investment.

3. High technical content

Using advanced production technology, the limestone dryer produced has a high degree of mechanization, which can realize the self-insulation of the cylinder, and the thermal efficiency can be as high as 75%.

4. Environmental protection

The equipment is equipped with an air box pulse bag dust removal device, which can effectively reduce the dust overflow of the equipment, avoid dust pollution in the production workshop, and create a good working environment for the operators.

Equipment Pictures

Customer Site

Technical Parameter

| Specification(m) | Cylinder volume | Capacity | Installation slope | Max intake air temperature | Main motor | Total weight |

| (Diameter x Length) | (m³) | (t/h) | (%) | (℃) | (kw) | (t) |

| Φ1.2×8.0 | 9 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |

| Indirect heat transfer dryer | ||||||||

| Cylinder diameter × Cylinder length | Inner diameter of outer cylinder (mm) | Inner cylinder inner diameter (mm) | Cylinder length (m) | Cylinder volume (m³) | Cylinder slope | Lifting plate type | Maximum intake air temperature (℃) | Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | lift type | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | lift type | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.1 | 3-5% | lift type | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 | ||||||

TOP

TOP  Email

Email Phone

Phone Online

Online