Product Introduction

The clay dryer is mainly composed of cylinder, lifting plate, reducer, gear, idler, stop roller, feed chute, front roller ring, rear roller ring, discharge part, pinion, motor, hot air duct, furnace Body structure.

When the clay dryer is working, the clay is sent to the hopper by the conveying equipment and sent to the feeding end of the clay dryer by the feeder, and enters the cylinder smoothly through the inclined feeding pipe. The cylinder is slowly rotating during the working process, and is inclined at a certain angle with the horizontal line. Clay enters the cylinder from a high place and slowly travels towards the low end under the action of gravity. At the same time, the heating medium is introduced from the low end and continuously impacts to the high place, making reverse contact with the clay material. The drying of the clay is completed in the process. In addition, the cylinder body is equipped with a copy board, which can continuously pick up and sprinkle the clay material, which greatly increases the contact area between the clay and the heating body, and improves the drying rate.

Performance Advantage

1. Convenient and fast operation: horizontal structure design, automation system, more convenient operation, less labor, and at the same time its small size, saving 70,000 yuan in installation, transportation, and infrastructure costs;

2. Super production capacity: The drying cylinder has a large volume, which can hold more materials, and the special design of the lifting plate can improve the drying efficiency and increase the production capacity by more than 60%;

3. Outstanding drying effect: the hot air has a large contact area with the material, the drying is more uniform, the material stays in the cylinder for a short time, and the quality of the finished clay powder is extremely good;

4. Good safety and stability: The selection of high-quality materials and sophisticated process design can effectively improve the quality and stability of the equipment, with stronger safety and no impact on the health of the operators;

5. Energy-saving and more environmentally friendly: low coal consumption, and can achieve comprehensive utilization of hot air, with good energy-saving effects. At the same time, environmental protection measures are better, and there is no pollution problem.

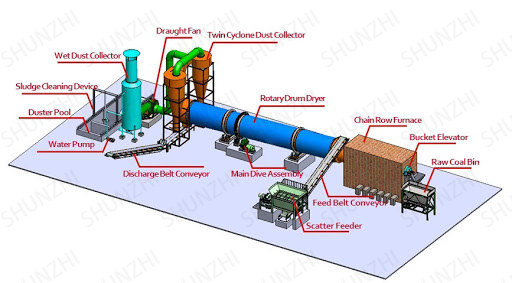

Equipment Pictures

Customer Site

Technical Parameter

| Specification(m) | Cylinder volume | Capacity | Installation slope | Max intake air temperature | Main motor | Total weight |

| (Diameter x Length) | (m³) | (t/h) | (%) | (℃) | (kw) | (t) |

| Φ1.2×8.0 | 9 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |

| Indirect heat transfer dryer | ||||||||

| Cylinder diameter × Cylinder length | Inner diameter of outer cylinder (mm) | Inner cylinder inner diameter (mm) | Cylinder length (m) | Cylinder volume (m³) | Cylinder slope | Lifting plate type | Maximum intake air temperature (℃) | Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | lift type | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | lift type | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.1 | 3-5% | lift type | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 | ||||||

TOP

TOP  Email

Email Phone

Phone Online

Online